Preview

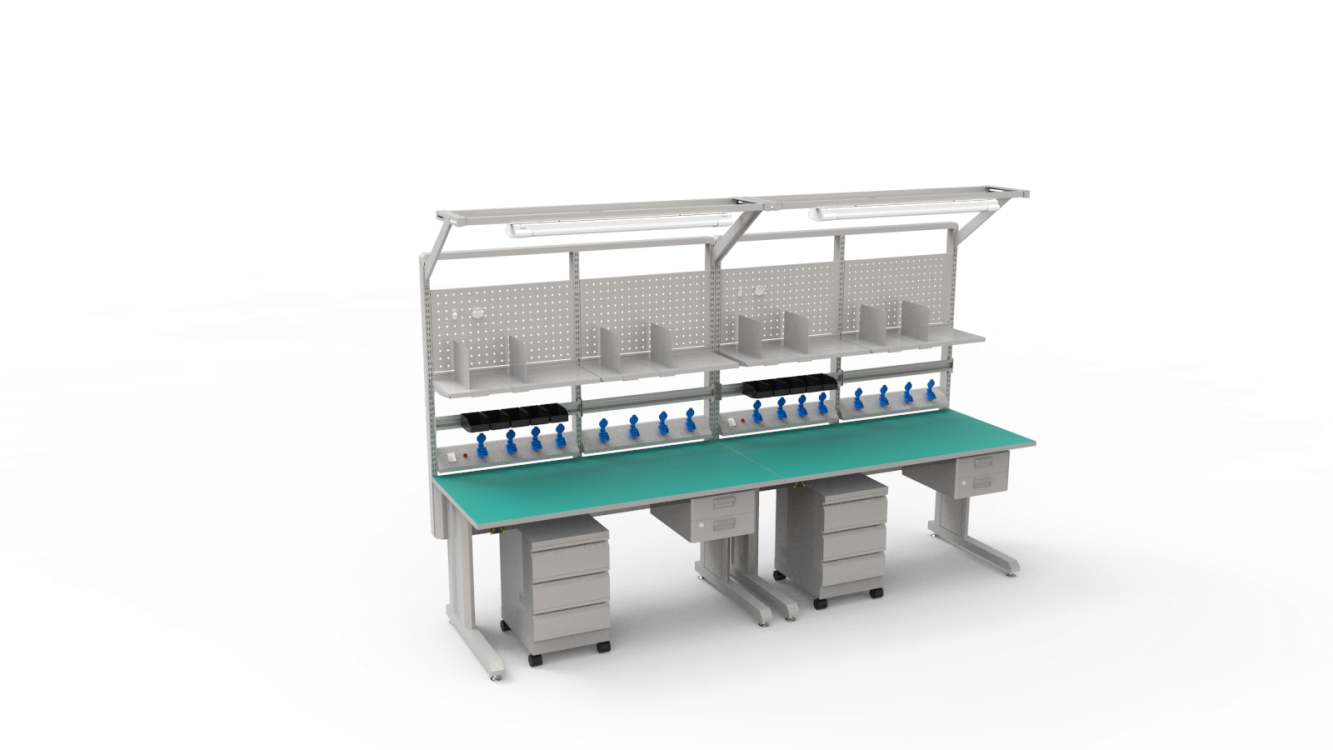

Test assembly workbench

Two units WA12 Test assembly workbench with green ESD table top,

Accessories :Two units side by side ;

Double drawer;

Movable tool cabinet;

Electricity :110V/220V AC sockets ;

Bins:bin rail with plastic bins;

Steel up shelf with dividers;

Up panel:M750*390mm;

Light system:LED light 40W;

Modular Test Assembly Workbench: Precision-Engineered for Electronics Testing & Assembly Efficiency

Engineered for electronics engineers, technicians, and R&D teams, our Modular Test Assembly Workbench delivers a versatile and scalable solution for electronics testing, prototyping, and component assembly.

Designed to streamline workflows while ensuring precision and safety, this workstation adapts seamlessly to diverse applications—from PCB validation to device development—thanks to its modular components and customizable configurations.

Core Features

Modular Design for Maximum Flexibility

Interchangeable Components: Swap or upgrade modules (e.g., test jigs, power supplies, sensor interfaces) to support PCB assembly, microcontroller testing, or RF circuit validation.

Adjustable Mounting Rails: Securely hold diverse devices (e.g., circuit boards, sensors, or prototypes) with adjustable clamps and anti-slip pads.

Integrated Testing Infrastructure

Multi-Channel Signal Routing: Built-in connectors for oscilloscopes, multimeters, and logic analyzers to monitor voltage, current, and signal integrity in real time.

ESD-Safe & Durable Construction

Conductive Surfaces: Black conductive epoxy worktop (surface resistance ≤10⁶ Ω) to dissipate static charges, compliant with ANSI/ESD S20.20 standards.

Reinforced Steel Frame: Powder-coated structure withstands heavy loads (up to 200 lbs) and harsh environments.

Collaborative & Ergonomic Workflow

Height-Adjustable Work Surface: Ergonomic design supports sit-stand transitions for prolonged testing sessions.

Cable Management Zones: Built-in grommets and Velcro straps to organize high-density wiring and reduce clutter.